Principle of Operation

The Clavis belt meters are based upon the natural frequency of vibration of the belt. The frequency of the belt is measured by the equipment and is directly related to the tension in the belt. As the tension in the belt increases the frequency of vibration also increases. This vibration is inaudible and not usually visible.

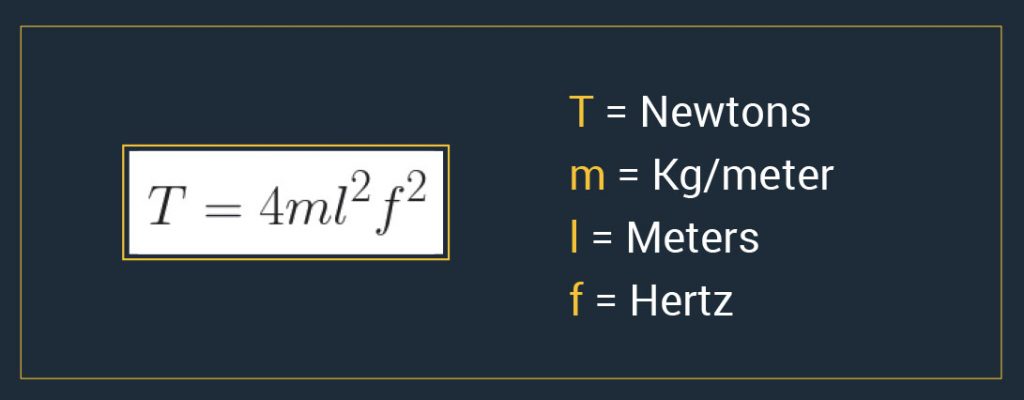

The relationship between the measured frequency and the tension of the belt should be determined from a calibration test on the belt span. The relationship between belt tension (T) and frequency of vibration (f) may be calculated from knowing the mass per unit length of the belt (m), and the belt span (l), using the expression;

Clavis use two different measurement techniques to measure belt frequency; Acoustic measuring air displacement, or Optical that uses an invisible infrared beam to detect vibrations of the belt.

Sensor Head

Clavis Belt Meter uses two different measurement techniques to measure belt frequency; Acoustic measuring air displacement, or Optical that uses an invisible infrared beam to detect vibrations of the belt.

Acoustic Sensor

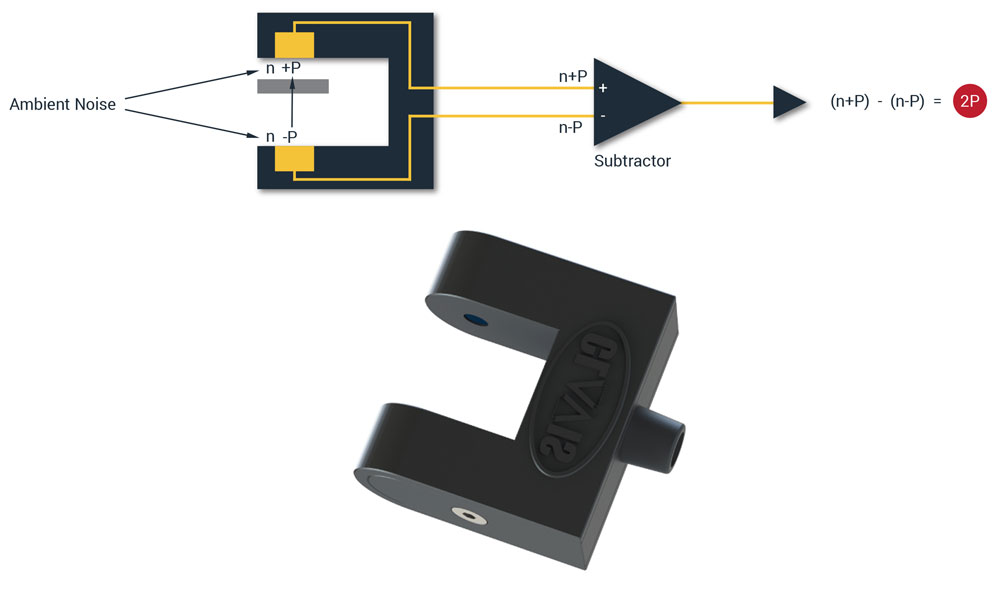

The acoustic sensor uses a Clavis patented technique for detecting the belt vibration signal whilst minimising ambient noise. The acoustic sensor is particularly suitable for belts which vibrate poorly or where the amplitude of belt vibration is very small. The ‘jaws’ of the sensor should be positioned over the centre of the belt and placed mid length of the belt span. The sensor should not be allowed to touch the belt as this will reduce the belt vibration signal. A range of sensors is available to suit belts of differing widths. The standard Type 3 sensor is suitable for all automotive applications.

When the belt vibrates upwards a positive pressure is exerted on the top microphone and negative pressure on the bottom microphone. External ambient noise falls equally on both microphones. When the microphone output signals are subtracted the background noise is eliminated and the belt vibration signal is doubled.

Optical Sensor

The optical sensor uses an invisible infrared beam to detect vibrations of the belt. A narrow angle orange LED generated beam is provided to guide the aiming of the sensor.

The best signal from the belt is seen when the sensor is held perpendicular to the belt at the centre of the span at 9,5 mm (3/8 in) distance. When physical restrictions are present, it is possible to get useable readings with the sensor up to 50 mm (2 in) distance from the belt and/or tipped up to 45° from perpendicular.

It is possible to take measurements from the edge of the belt. The toothed side of a belt is equally acceptable as a target for the sensor. The sensor LEDs should be kept clean by wiping with a soft cotton cloth. Solvents are never to be used.

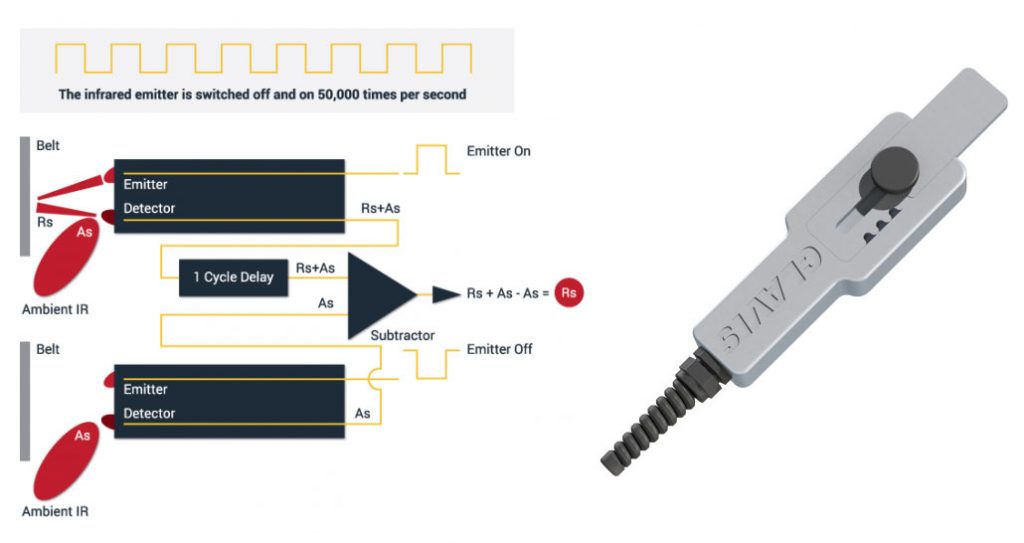

When the emitter is ‘ON’ the detector sees both the reflected belt IR signal and the ambient IR signal. When the emitter is ‘OFF’ only the ambient IR signal is detected. Subtracting the two signals results in only the IR reflected belt signal.