In many applications where the Clavis belt tension measuring equipment is employed there is a requirement for a Quality Assurance (QA) procedure that all equipment used should have a calibration check performed at periodic intervals. Although all Clavis equipment may be returned to the manufacturers for the issue of a certificate of calibration, many QA procedures require that a daily or weekly check be made.

Sonic Calibrator

The Clavis calibrator is a portable unit which drives a vibrating transducer at precise frequencies within the range of 30 to 600Hz. The transducer is inserted between the sensing head of the belt tension meter and a comparison between the measured frequency and the driving frequency is made. The calibrator automatically steps through the frequency range in 50Hz intervals. All Clavis calibrators are issued with a certificate of calibration traceable to national standards.

The calibrator and vibration transducer are supplied in a carrying case. The unit is powered by 4 standard AA size alkaline batteries.

Resonator

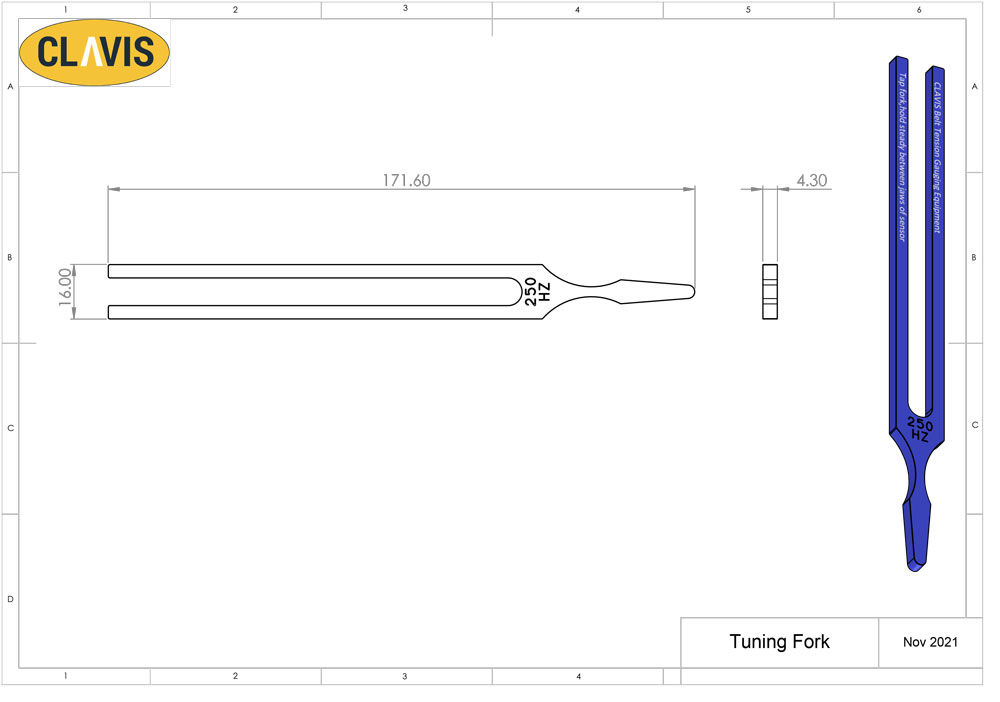

Every Clavis meter is supplied with a precision mechanical resonator or tuning fork for simple calibration validation by the user. The resonator is tapped on a hard surface and then held between the jaws of the sensor head. The resonator vibrates at 250Hz and a corresponding value should be repeated on the meter.

Calibration Rig

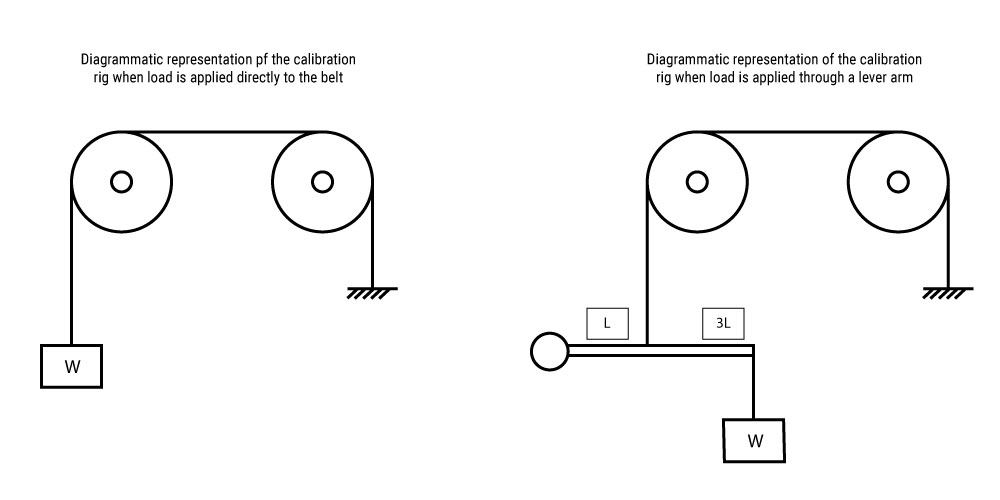

For the highest orders of accuracy, a dead weight belt calibration translates belt frequency to belt tension. Using the calibration rig a belt is split and supported over the actual pulleys of the application. The pulley centre distance is also set to match the centre distance of the application. The free end of the belt is loaded by weights, either directly or by a 4x weight multiplication arm. Precision weights are progressively added, and the corresponding belt frequency is recorded at each increment. A graph of belt frequency against tension is then drawn which can be used as the reference for future belt tension measurements.

The calibration jig may be purchased by users who have many belts to tension and who maintain their own standards facility. Clavis are pleased to undertake such belt calibrations in our own standards laboratory for all their customers as a free of charge service.

Although the calibration rig simplifies belt calibration the direct belt loading method shown above may be replicated easily possibly on the actual application itself.

By simply extending the lever arm the load magnification may be increased. The standard calibration rig can perform belt tension calibrations with belt loads up to 2000N.