When power-assisted steering first emerged, the industry — including road testers — didn’t like it very much. Yet, electric power assisted systems (EPAS) are vital in today’s modern vehicles. Here, I explain what shifted opinions and why effective belt measurement is vital for the power-assisted systems of today and tomorrow.

“The horse is here to stay but the automobile is a novelty — a fad,” said the president of Michigan Savings Bank in 1903, advising against investing in Ford Motor Company. We can laugh at this now, but power-assisted steering technologies also took a while to take off.

The first systems were all-hydraulic. When the driver turned the wheel, this put mechanical force into the steering gear, while pressure generated by a simple engine-driven pump forced fluid through the system. However, these hydraulic systems were something of a drag on the car’s fuel supply.

So, what changed — and how did the systems become more popular?

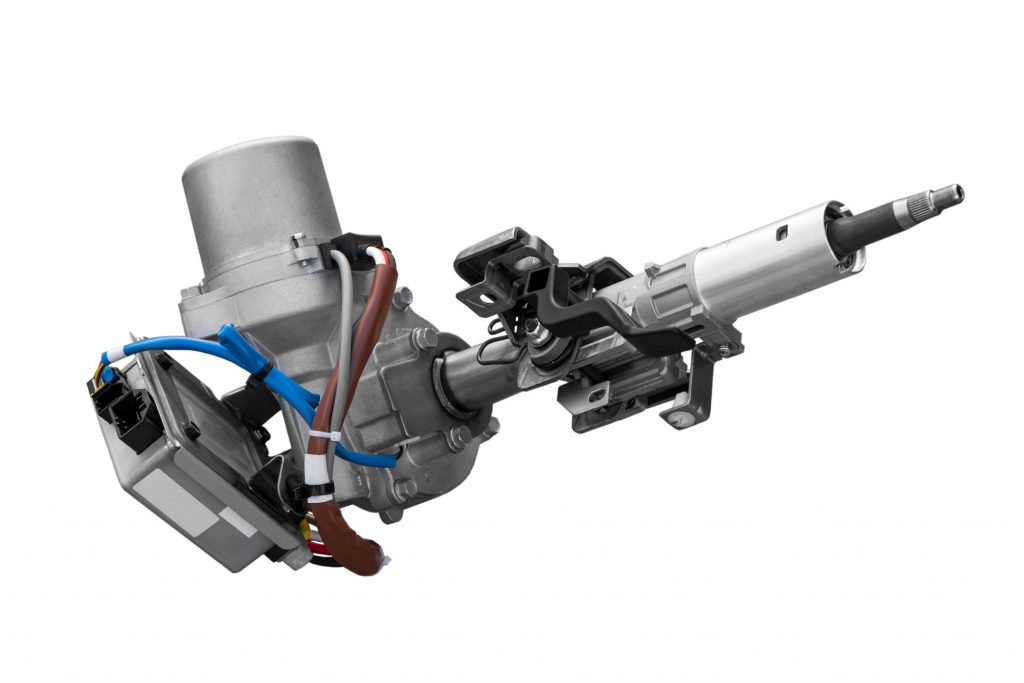

A major reason was the advent of electric power assisted systems (EPAS). Electro-hydraulic systems follow the same principle, only the power steering pump is driven by an electric motor, rather than the engine. A major reason EPAS has become popular is fuel economy. And let’s not forget driver comfort.

As cars became heavier and more difficult to steer, electric-assisted steering emerged has become lighter and smaller than hydraulic systems, and is therefore preferable. Although, just like your mate who insists vinyl is the best-sounding format, some say that electric-assisted systems don’t offer the same steering feel as hydraulic assistance.

There have been various types of hydraulic-powered steering pumps.

Nevertheless, EPAS systems are essential and will continue to be into the future. Like most other forms of evolving tech, EPAS systems will continue to get smaller and more compact — plus we have wireless steering and braking systems to look forward to, which I wrote about here. In all cases, effective belt measurement systems will be needed.

Clavis first got involved with EPAS systems in 2004 with our customer, Delphi. We heard the customer had started manufacturing EPAS systems and, because they relied on our handheld belt tension meters, we reached out to them. Would it be possible for us to update our belt measurement system, the FourierBMS, to better suit the requirements of EPAS technologies?

EPAS systems present unique challenges for effective belt measurement. These mainly relate to accessing the belt, which is small and confined. An effective belt-measurement system must therefore strike a balance between accessing the belt while also locating, and reaching, the best area for a reading to be taken. That’s where a system like the FourierBMS comes into play, to successfully strike the balance between accessibility and accuracy.

In short, the FourierBMS comprises a main unit with a sensor head. Our specialists work with each customer to design the sensor head unique to their requirements — as you’ll see in the photo, we’ve amassed more than 50 sensor head designs and counting. Each new bespoke design gets added to the catalogue.

Clavis continually designs new, bespoke sensor heads to reach nooks-and-crannies in customers’ EPAS systems.

These EPAS units are now being mass-produced. Often, the FourierBMS sensor head will be affixed to the end of a robot arm and, again, must agitate and read the belt at the most accurate place. These capabilities are why there aren’t many belts worldwide that aren’t tensioned with the FourierBMS. And why the system can apply to other areas like agriculture and marine engines.

Which brings me to my next point: Industry 4.0.

Aside from FourierBMS’s sensor head, there is also the unit itself. In the case of the FourierBMS 001, we’ve designed it to do everything in one box. The box contains an integrated programmable logic controller (PLC) with Profinet connectivity for data communication over Industrial Ethernet, and enhanced inputs/outputs (I/O) for Industry 4.0 compatibility. The FourierBMS can connect into, or create, closed loop systems where no human input is needed.

Today it’s clear that no-one could call EPAS systems a novelty or a fad — to paraphrase the president of Michigan Savings Bank. Going forward, we plan to develop these capabilities further with smaller, wireless sensor heads to support tomorrow’s more compact power-assisted steering systems.

Article by Andrew Punton