Performance

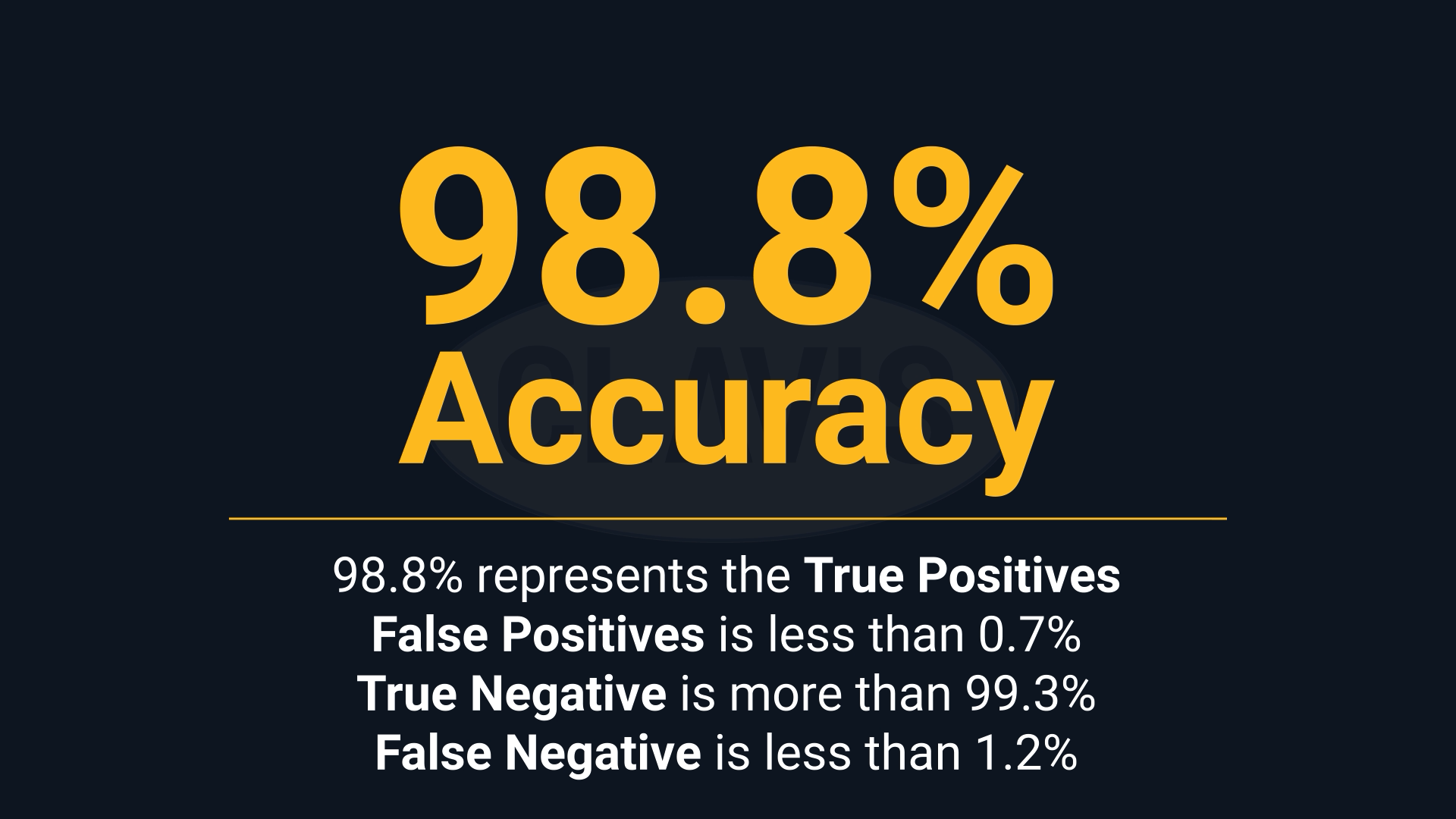

98.8%

98.8% represents the True Positives

False Positives is less than 0.7%

True Negative is more than 99.3%

False Negative is less than 1.2%

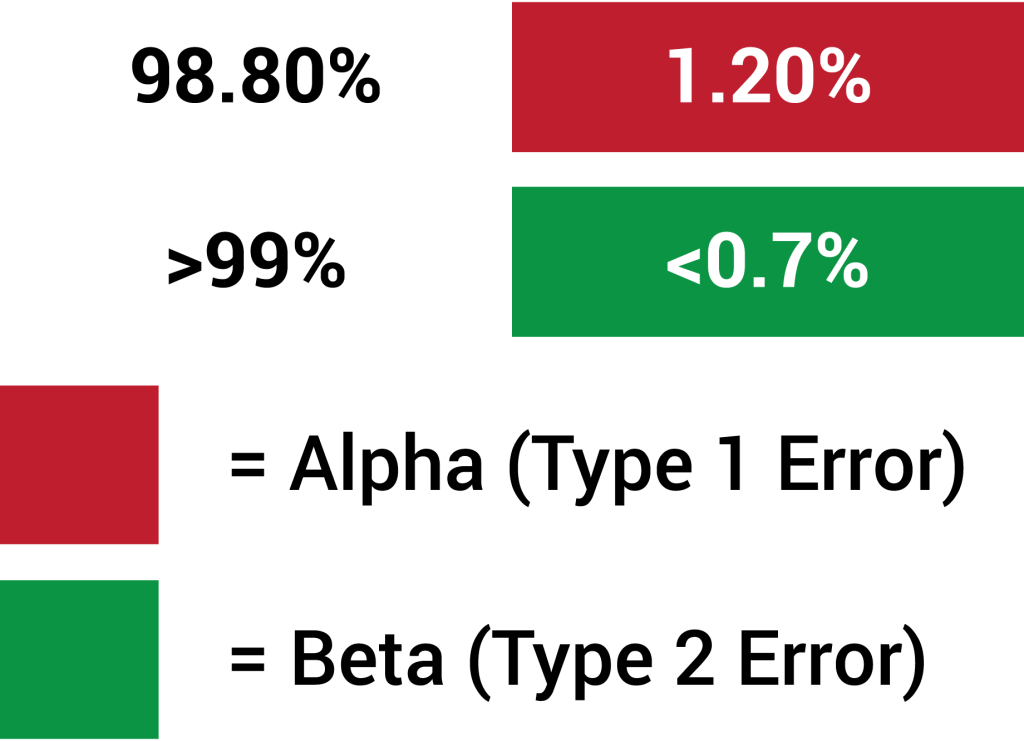

GUSTO STATISTICS EXPLAINED

98.8% Represents the True Positives

If the Gusto Tool experiences 100 vibrations it will be able to accurately classify 98-99 of these vibrations as “Clips”.

False Positives is less than 0.7%

If the operator dropped the tool or hit it on the engine while accessing the clamp, the Gusto tool will be at a risk of giving one false green led (OK) for every 100 vibrations that was passed to the tool.

True Negatives is more than 99.3%

The gusto tool will be able to accurately classify a vibration that wasn’t from a clamp being released as a “Hit” once out of every 100 vibrations passed to the tools from hits 99 of these will be classified correctly.

False Negative is less than 1.2%

If 100 clamps are released using the Gusto tool approximately 98/99 of these clamps will be correctly classified as a “clip” with the risk of missing one or two clamps per every 100.

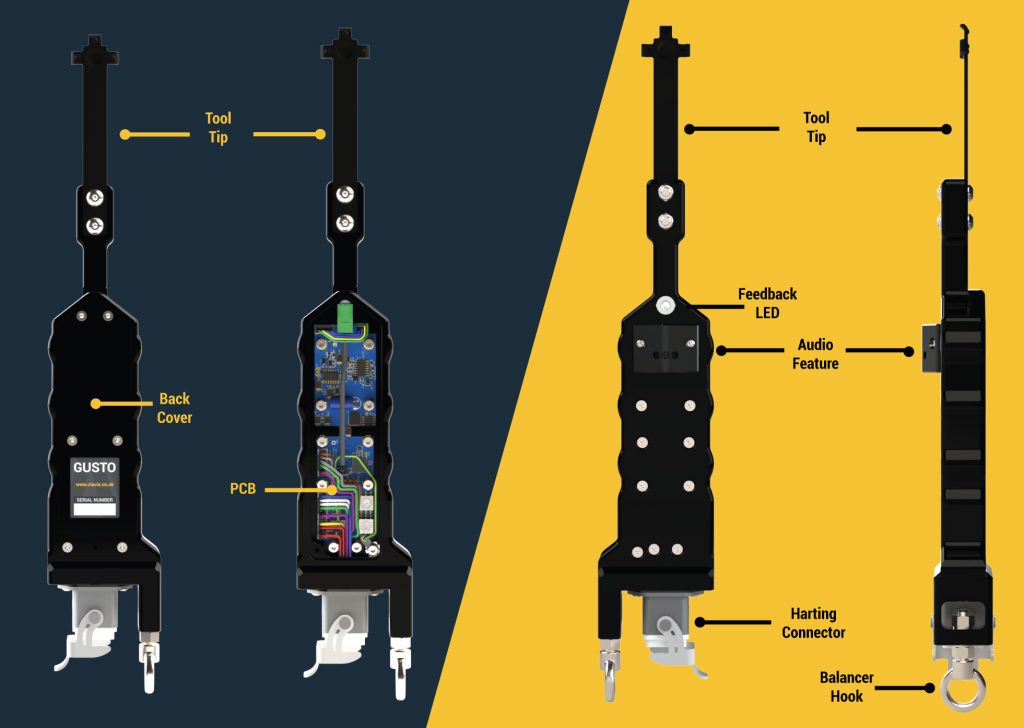

GUSTO OBSIDIAN TOOL FEATURES

- 6-Axis Inertial Measurement Unit (IMU) containing a 3-axis gyroscope & 3-axis accelerometer.

- An acoustic sensor integrates a dual-microphone set up for environmental noise cancellation and signal isolation.

- Aluminum Housing.

- Tri-colour LED for instant operator feedback.

- Interchangeable tips.

- Industrial quick release connector.

- Industrial cable - up to 30m.

- One tool/code for all clamp sizes.

- Built-in diagnostics menu.

- Ability to detect and reject accidental false triggers.

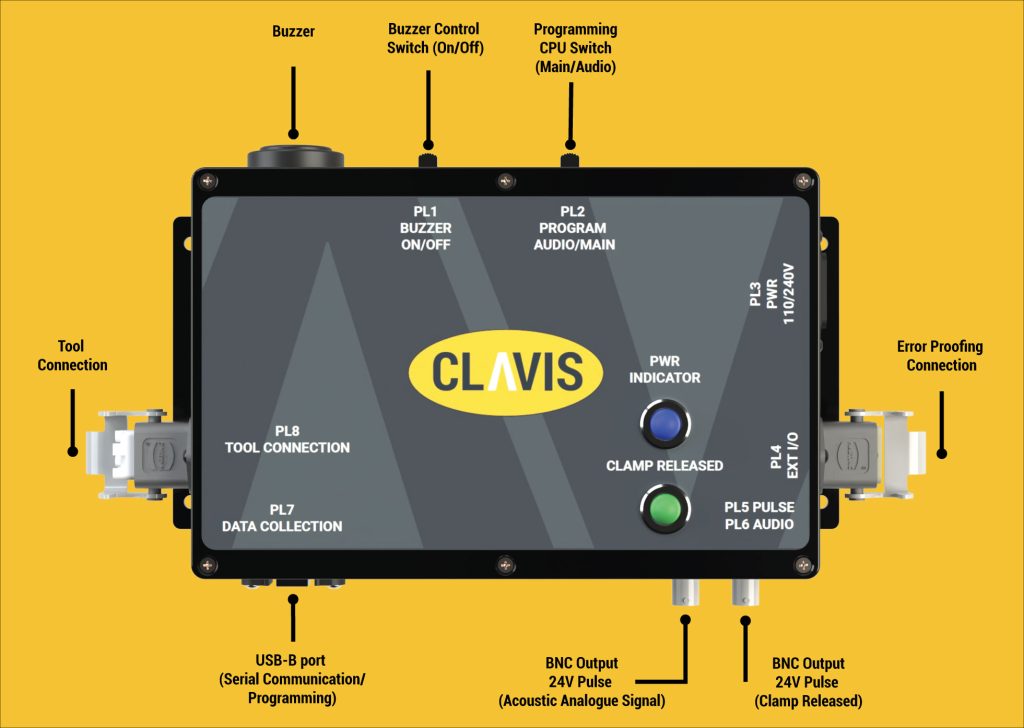

GUSTO OBSIDIAN INTERFACE BOX FEATURES

- Separate LEDs indicating power and clamp released.

- USB-B port provides both serial communication to both MCUs within the tool and programming functionality.

- Buzzer - provides an acoustic (40-90 dB) feedback when a clamp is released.

- Error Proofing Connector for plant connectivity.

- BNC Outputs - 24V pulse when a clamp is released & will output the acoustic analogue signal from the microphone.

Want to know more?